Various valves are used in plumbing systems to regulate the flow of water while also connecting the pipes. Furthermore, a wide range of valve designs is suited for various circumstances and services, including multiple uses, fluid management, materials, and temperature and pressure settings.

Plumbing valves are used in plumbing and other fluid applications for preparation and stopping the flow. Throttling and controlling flow, and preventing and regulating pressure. It is essential to choose the right valve for your plumbing system. An important reminder for plumbers seeking the best valve to match their needs.

Let’s look at the many sorts of valves that are used in plumbing:

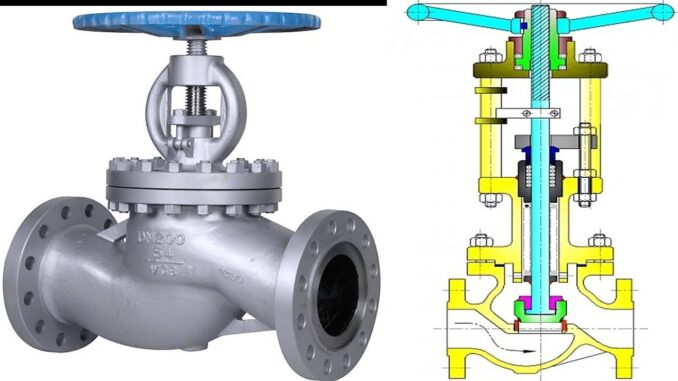

1. Globe Valve

Source:youtube

A globe valve is a type of valve that is widely used to start, control, and halt the fluid flow. This valve is specifically designed for systems where leak tightness is required. Requiring leak tightness and flow control is highly recommended. When compared to gate valves, a globe valve can give a superior shutoff.

When the water flow must be controlled, or you need immediate modifications, these valves are the best option. On both ends of this valve’s internal design characteristics is a stopper.

Globe valves are ideal for outdoor faucets and similar utility faucets. This is because they are typically appropriate for controlling flow. Globe valves come in various shapes and sizes, including Y types, Z types, and Angle kinds. It may also be pricey in terms of cost, depending on the materials utilized.

2. Gate Valve

Source:thomasnet.com

When it comes to plumbing applications, gate valves are the most popular choice. The water flow is controlled by lowering and raising a specific internal gate using a twist-type knob or lever. The top of the valve has a knob that should never be used to adjust the flow volume.

Keep in mind that these plumbing valves are meant to open and seal entirely. When it’s open, it allows full flow. It completely stops the flow when closed.

There are five types of conventional gate valves available:

- Rising Stem valve and OS & Y Gate valve

- Parallel disks valve or Split wedge

- Flexible wedge gate valve

- Solid wedge gate valve

3. Butterfly Valve

Source:ksb.com

Butterfly valves and ball valves are similar in one way. They both feature a lever-type handle that shuts and opens the valve. A metal disc is used to alter the flow of water in this design. Even though the valve is fully open, the water is at the center of the valve. Or it is flowing around the disc, and the flow is considerably decreased.

When compared to ball valves, this is a better option. A butterfly valve can precisely control the flow volume. The gasket within a butterfly valve is one of its most apparent flaws. After a few years, it may create some maintenance difficulties.

4. Check Valve

Source:edmundvalve.com

According to frisco tx plumbers, Check valves are commonly used in water tanks to control flow. You can also operate them automatically. Its purpose was to prevent water from flowing in a single direction. The check valve is also known as a non-return valve. This is because it may avoid back-flow inside the pipe system.

For quicker operation, the majority of these valves are spring-loaded. Check valves come in a variety of shapes and sizes.

- Spring and piston checks stop reversed flow using a spring-loaded plunger in a piston check valve.

- Wafer and swing check valves frequently stop reversing flow within a flap. The flaps close around the seat. Only a forwarding flow is utilized for swing checks; it might be vertical or horizontal upward.

- Ball check valve – since the flow is slower, the ball of this check valve frequently slips right into a hole. For semi-fluids like pulp or effluent, a ball-check is strongly recommended.

5. Needle Valve

Source:pamline.com

In terms of design, these valves are more akin to globe valves. The pointed needle-like disc is the sole notable distinction between these two valves. This type of valve is designed to manage flow in pipe systems with a smaller diameter with precision and detail. The sharp and pointed conical disc and corresponding seats on this valve give it its name.

This valve’s closing shaft acts as a stopper with tiny holes. It is mainly used to control the flow of water. The valve’s accuracy, design, and stability ensure a good seal despite the enormous pressure differences. It serves as a typical bypass to the ball valve in a hydraulic system before the turbines.

5 Critical Factors to Consider in Plumbing Valve Selection

Source:wattsau.com.au

Valve selection for plumbers is frequently based on the logic of each action and safety. Also, the expertise gained from a rigorous and complete balance comparison. Selecting project management software as an essential tool for monitoring and tracking plumbing projects is advantageous.

Furthermore, it is crucial to look at some critical factors. Better to ensure you choose the suitable plumbing valve from various options available today.

1. Media Type

The valve material that must be utilized is determined by the properties of the liquid type being regulated. PTFE and PFA are excellent alternatives for monitoring corrosive and abrasive compounds. Since they can tolerate and sustain these severe environments. To provide the maximum degree of safety while tracking pressured gases, use metal valves.

2. Valve function

Determine what the valve needs to fill in first. When it comes to on/off control inside a system, two-way valves appear to function admirably. Three-way valves are an excellent choice for on/off control, as well as mixing and diverting media.

Also, keep an eye on whether the valve is open or closed. As it cannot be the other way around. Order valves manufactured of high-quality materials and in a specific orientation to extend the life.

3. Application Conditions

One of the most critical aspects in selecting the proper valve application is determining the correct valve size. A valve that is too big or too little might cause problems in the system or elsewhere.

Make a note of the flow rate, temperature, and pressure that these valves will operate at. Globe valves, in many situations, can resist higher pressures and temperatures than plastic valves.

4. Actuation Method

Another point to think about is how the valve should be operated. Determine if the valves are manipulated manually or need to be triggered to turn on and off automatically. If you choose the latter option, make sure you decide on the units you’ll employ. A hydraulic, electric or pneumatic actuator should be used in conjunction with it.

5. Pressure Class

In many situations, the established pressure class is used to determine the valve’s pressure. Otherwise, one can find the pressure class of the utilized valve by the combined force, bonnet materials, and temperature.

Furthermore, it is an essential component that no plumber or buyer should overlook. The media typically influences the choice of building material for this valve. Ascertain that the pressure class and medium material are compatible.

Key Takeaways

Source:qingguanvalves.com

The list contains various typical types of valves used in plumbing applications. Although it is far from comprehensive. Essentially, the best valve for you will be determined by the application.

Before choosing the finest plumbing, be sure to emphasize the essential elements that we discussed above. You can also make better decisions by being wiser and more practical. Choose the best industrial valve SIO as the manufacturer for your next project! Click here for more information.