Though every industry comes with its own set of risks for workers, the employees in the Oil and Gas industry fall well and truly under the category of a high-risk working environment as compared to other sectors. According to the 2015 report of the Bureau of Labor Statistics, 74 out of 120 workstation deaths in the oil, mining, and gas extraction industry are within the support activities. It means that the industry is not really considering the safety processes to ensure a secure working environment for the workers. The safety of the workers should be the priority of any business regardless of the industry. However, it seems that the oil and gas industry needs to rethink their safety plan.

There is no denying that the continuous pressure of productivity, long workdays, and constant physical effort takes a heavy toll on employees. All these factors combined can greatly influence safety by increasing human error. So, how to deal with all this fuss? How to make the work environment safer than before for the employees? How to handle the stress in the industry? If you want to learn the answers, continue reading.

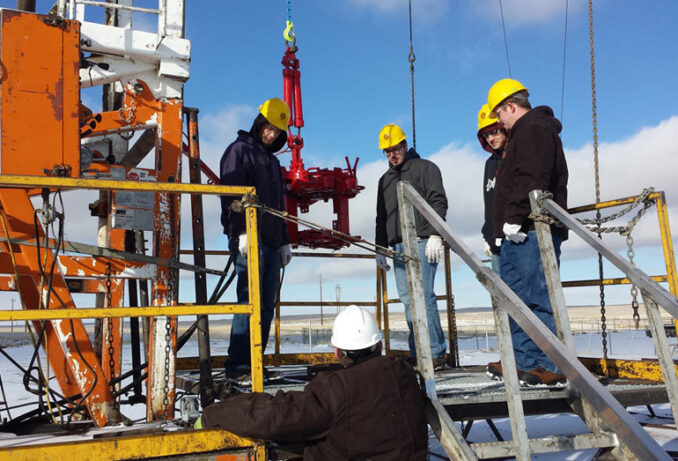

Source:vestnikkavkaza.net

1. Maintain Basic Safety Measures

Slips, trips, falls, and other workplace hazards can be best avoided with good housekeeping. In fact, establishing necessary safety measures is an essential element of process safety. For this, you need to make sure that you are keeping walkways clear from debris. If anything spills, it should be cleaned immediately. Doing so will help prevent the chance of fatal accidents in the workplace. According to Burwell Nebout, even if any tragedy happens or workers are injured during the job, they can consult with Personal Injury Lawyers to receive compensation. However, it is better to prevent the accident from happening in the first place. Also, here is compensation attorney pothitakislaw.com which can help workers in these situations.

Also, ankinlaw.com can help you in these cases.

2. Monitor Mental Health Of Workers

In recent years, every industry has become more aware of the mental health of the employees. However, the question is, does the oil and gas industry emphasize workers’ mental well-being? It seems no. Worker culture is one of the main factors that negatively affect safety in the industry. If the worker is not mentally or emotionally well, it can influence everything. For this, the oil and gas industry needs to bring products and training that monitor the mental health of workers. Without this support, stress and loneliness can lead to self-harm and even suicide.

3. Be Aware of all Hazards

Source:wcartc.org

If you ignore minor hazards today, you will have bigger problems tomorrow, especially within the oil and gas industry. In this industry, there is always a probability of happening something unusual, so nothing should be taken lightly. If you notice anything unusual, you should make a quick decision to control the situation before it’s too late. In addition to this, you need to make sure that smaller incidents are regularly recorded to keep a firm hold of the circumstances and to avoid any safety issues from growing.

4. Do Not Overlook Machine Maintenance

When you are quite a few miles away from the shore, everything depends on the machines while working on the offshore rigs. Therefore, you need to conduct regular maintenance checks to prevent premature machine failure. It will also avoid any accident that could take place due to the machine not operating well. Be sure to clean debris and dirt from the machines and oil the components regularly to make sure they are running smoothly.

5. Never Stop Learning

No matter which industry you are in, the learning process should never end. Particularly, when it comes to the oil and gas industry, your priority should be learning and sharing the best safety practices all the time. After all, it can keep you and others working around you safe. Additionally, the industry recognizes the significance of teamwork and engages the workforce via offshore safety working group and onshore networks. The oil and gas industry arranges workshops and seminars to aware workers about the safety procedures they can follow.

6. Ensure Familiarity With Worksites

Before you even start working, make sure you are familiar with the area you will be operating in. Every worker needs to certify that he understands his roles, hazards that may exist, and know what to do in case of an emergency. To know better about the risky areas, you can communicate with the workforce or people working there before your shift. The crew knows about all the entry and exit points of an oil rig or whatever environment you work in the industry. Therefore, by communicating with them, you will better be able to understand where the risks lie.

7. Do Not Neglect Safety Signage

Source:safety4sea.com

In the oil and gas industry, most projects hire contract labor. It means workers are not likely to be familiar with the layout of the worksite, equipment, and procedures. In such cases, workers may rely on professional training and experience to navigate the work location. However, there is one more, and probably the most important thing is the use of safety signage. To identify hazards and dangers, safety signage makes the most critical component of workers’ overall safety plan. These signs come in various categories, such as danger, caution, notice, special, fire safety, directional arrow signs, and safety instruction signs. All these signs are used to communicate and prevent specific dangers or hazards in the worksite. Moreover, when the project changes, take the time to certify that signs are in the correct areas before the next project begins.

Source:digitalistmag.com

8. Always Look Forward

Finally, you should learn from past incidents and always be looking forward. Now, this might seem like obvious advice or tip, but companies seem not to pay attention to this safety approach. Most companies note the time since the last incident happened. This is not the perfect approach. Instead, you should document the number of incidents that occurred over a certain period. If you succeed in doing so, you will be able to figure out the reason for those accidents. This will also help you define the safety procedures and what you can do to prevent any incident. Above all, workers will stay safe in the future.